The Fersa Grinding Burns Solution

Article

In the DAT4.Zero Project, the Fersa Grinding Burns Business Case is designed to overcome a longstanding challenge in manufacturing: grinding burns.

Grinding Burns

This issue, crucial for industries ranging from automotive to aerospace, involves damage to metal parts due to excessive heat during grinding, affecting durability and performance.

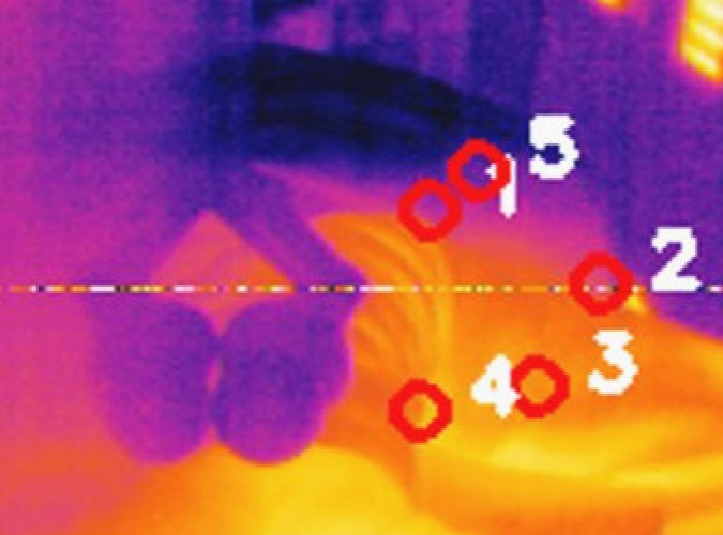

The solution developed by Fersa Bearings harnesses advanced sensors and artificial intelligence (AI) to detect these burns in real-time, allowing for immediate adjustments in the manufacturing process.

This innovation not only promises to enhance product quality but also to significantly reduce waste, marking a stride towards sustainable manufacturing. The system includes a temperature control mechanism, dedicated to overseeing the heat produced during grinding.

The Advantages are clear: it increases the reliability of manufactured parts, cuts down on waste, and sets a new standard for smart manufacturing practices.

It embodies the goals of the DAT4.Zero project by demonstrating how digital technologies can streamline manufacturing, improving both efficiency and sustainability.

Next steps

Next steps include expanding this technology across various sectors and further integration with digital manufacturing tools. The aim is to not only address the immediate challenge of grinding burns but also to inspire a manufacturing evolution across Europe.

By showcasing the benefits of this innovative approach, DAT4.Zero is driving the industry towards a future where manufacturing is smarter, greener, and more efficient.