IDS compliant interoperability for digitally enhanced quality: exploitation with UCIMU

Article

Stefano Borgia, 03/05/2024

IDS exploitation with UCIMU

The introduction of 4.0 tools and methods for ZDM into existing production environments faces big challenges not only in terms of data management and analysis for machinery and legacy systems, but also at the level of data integration and interoperability. The concept itself of interoperability, defined as “the ability of two or more systems/components to exchange and use information”, extends the industrial ecosystem outside the boundaries of the single factory, involving the various actors of the value chain in a virtuous and collaborative process aiming at achieving efficiency and digitally enhanced quality through secure data sharing.

While Industry 4.0 is leading the companies to adopt connected industrial equipment by getting new machinery or revamping the existing ones, interconnection capability is currently exploited only in a minor way respect to its theoretical designed use: there is the IIoT technology, but the missing part concerns mature business models and tools enabling trustworthy exchange of data among more companies.

According to this context, the aim at enabling and combining interoperability, security, and data sharing has been addressed by DAT4.ZERO project with the adoption of the International Data Space (IDS) paradigm and its main features.

The benefits of this endeavor are manifold. By integrating advanced sensors and employing artificial intelligence, ENKI is set to experience a reduction in scraps and an increase in production rates. This translates to offering higher quality products at lower costs and with shorter lead times for the development of new products. Moreover, the introduction of an augmented reality visor promises not only enhanced product quality but also improved working conditions for operators.

While the technical activities performed by Holonix Srl has led to the development and cloud deploy of an IDS wrapper of the REST interface of the Data Management System (DMS) software solution and to the full demonstration of the working of an IDS connector and the related open-source components enabling further production scenarios for the ENKI end user, exploitation activities are addressing the application of the proposed technical solution and the related approach in other contexts.

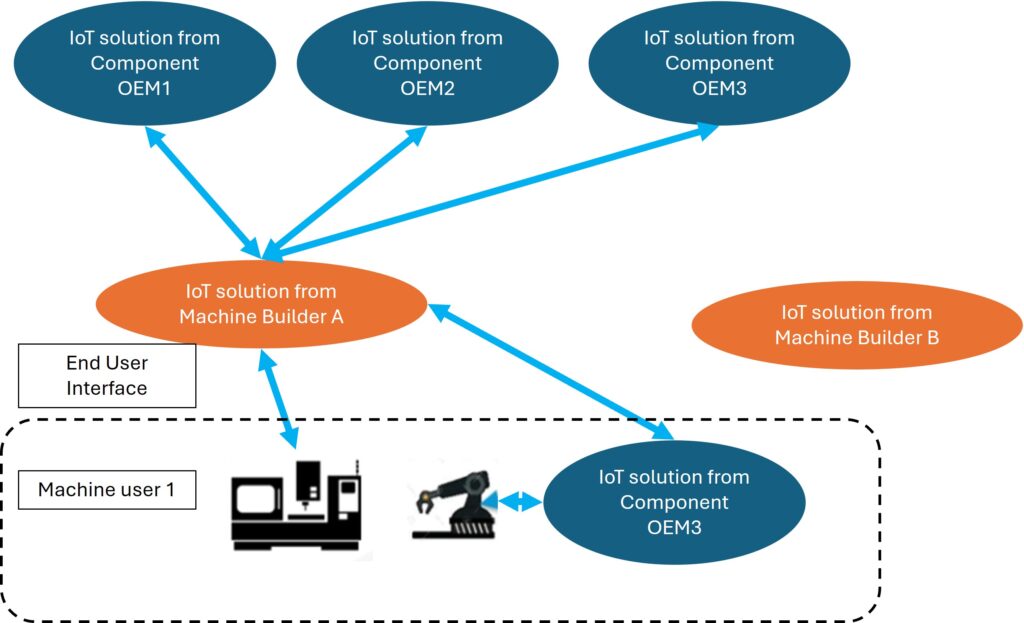

The presence of Holonix in UCIMU (association of Italian builder of machine tools) and its position inside the working group on prediction maintenance have allowed the creation of the UCIMU Data Space committee and to the definition of focused use cases where IDS work made in DAT4.ZERO project can be adapted and exploited. According to the manufacturing context and to the machine tool sector, data sharing faces also a high degree of complexity due to the presence of many machineries from different producers, a lot of components and a wide range of elements to be controlled.

The incremental and bottom-up activities (fully industrially funded on the base of voluntary basis) are leading to the implementation and training of a prediction maintenance system requiring the availability of data from the machine during its operating cycle, from the intelligent sensorized components and from the auxiliary equipment, where the secure and controlled exchange of information between the user of the machine, the supplier of the machine and the suppliers of components/subsystems is the fundamental element. Here the Data Space paradigm is the way to enforce this requirement, providing the right support to manage both technical and legal-contractual aspects.

Among the addressed production scenarios, the main one involves not only the machinery in use but also the other industrial equipment “working” together for the execution of a certain process or for the realization of a given product. The machine user shares data with the machine builder. The same user shares with the machine builder also the data monitored and gathered from the auxiliary components supporting the machine use. So, the machine builder can use all these data in an aggregated way.

The IDS technical solution has been cloud deployed and executed in a demonstration release. At the level of data structures, OPC-UA UMATI taxonomy has been taken as reference, avoiding vocabulary implementation. The diagnostics leverages existing systems currently used by the machine builders that have joined the UCIMU working group. The last step of data aggregation and analysis is currently on going, with the goal to present all the results in a specific dissemination event at the incoming BI-MU 2024, i.e. the international biennial exhibition dedicated to the manufacturing industry of metal cutting and forming machine tools, robots, automation systems, digital and additive manufacturing.

For further info about IDS exploitation with UCIMU, please write to stefano.borgia@holonix.it (Stefano Borgia, Holonix Srl).