DAT4.Zero: Cutting-Edge Technologies for Predicting and Preventing Manufacturing Defects

Article

The need

The manufacturing processes in general, and grinding processes in particular, require in-depth analysis for optimization and control due to the large number of parameters and variables influencing their behavior. The occurrence of defects of various kinds in ground parts poses a serious production problem that can result in scrapped or reworked parts, leading to productivity loss. The use of predictive models emerges as a useful tool for defect detection during the process.

To achieve this, and given the difficulty of theoretically modeling these processes, experimental data is necessary for the utilization of hybrid or data-driven models. The management system for these heterogeneous data must have certain indispensable characteristics for the correct functioning of predictive models: sufficient sampling frequency, adequate response speed, time-stamping and traceability of different data sources, or the ability to work on the Edge. In this way, it ensures that the system response is reliable, fast, adaptable, and accurate.

The system

The digitally-enhanced data monitoring and management system, DANOBAT BOX, therefore presents itself as the appropriate tool to meet the aforementioned needs.

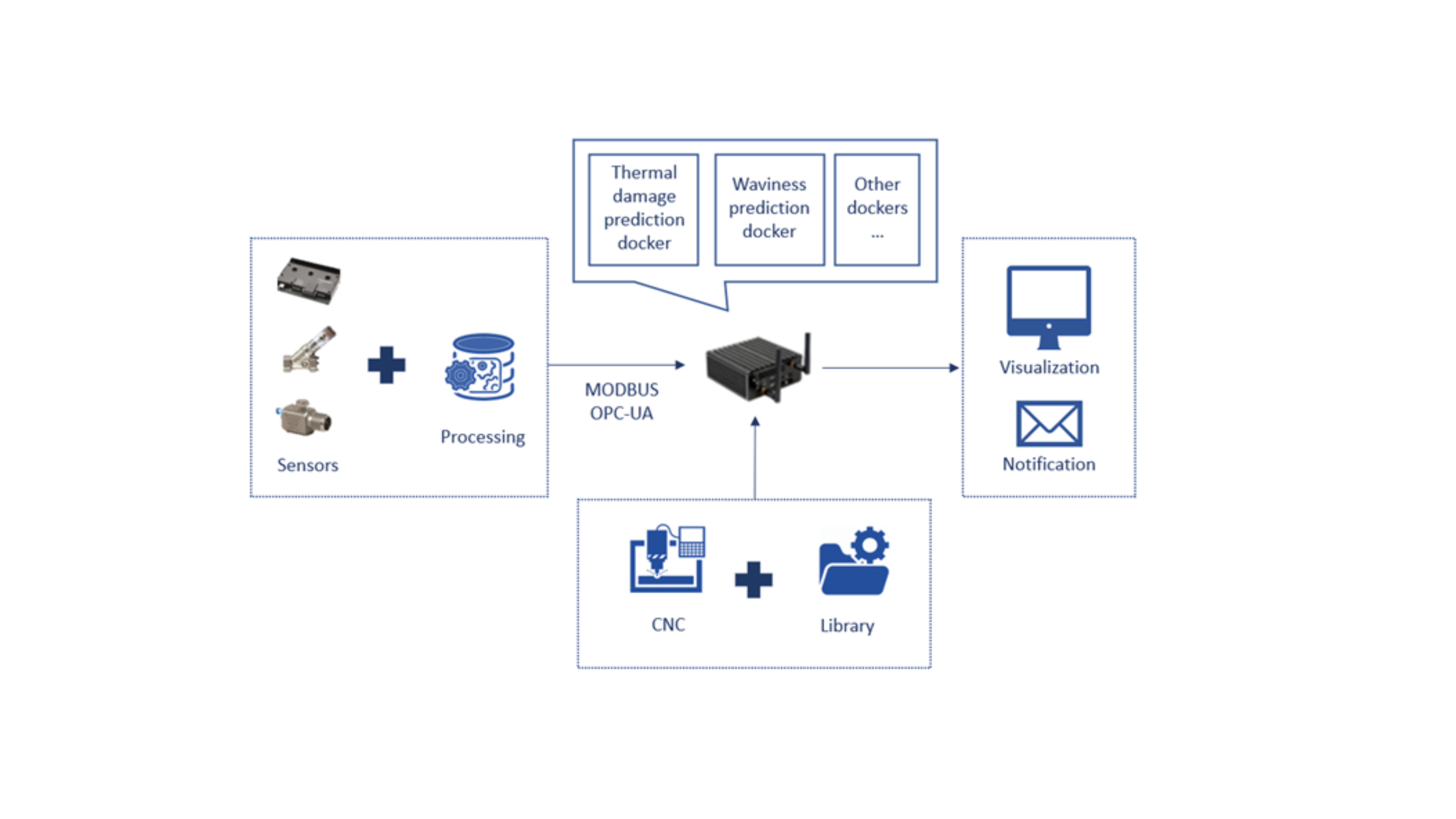

Figure 1. Danobat Box system and the interoperability.

The digitally-enhanced monitoring system is a data gathering device capable of connecting and gathering data from different types of machine-tools, external sensors and other sources. The device also enables interoperability with plan production management systems or with other Danobat Boxes. This system provides local storage of the acquired data, allowing manual download if necessary. Customized and embedded software applications can be integrated into de system using docker technology for data processing, data analytics, machine learning and visualization. Connectivity with the Danobat Cloud, the customer’s cloud or other platforms, as in the DAT4ZERO project, is possible.

As an indispensable component, DANOBAT PAC is a pre-processing device for acquiring the necessary data at high frequency, such as vibrations, and performing real-time processing and analysis to obtain useful indicators that can be managed by the system more efficiently.

The application

Within the DAT4.Zero project, the system has been adapted to the specific needs of FERSA bearing manufacturing in the pursuit of defect-free grinding processes, such as surface waviness or grinding burns.

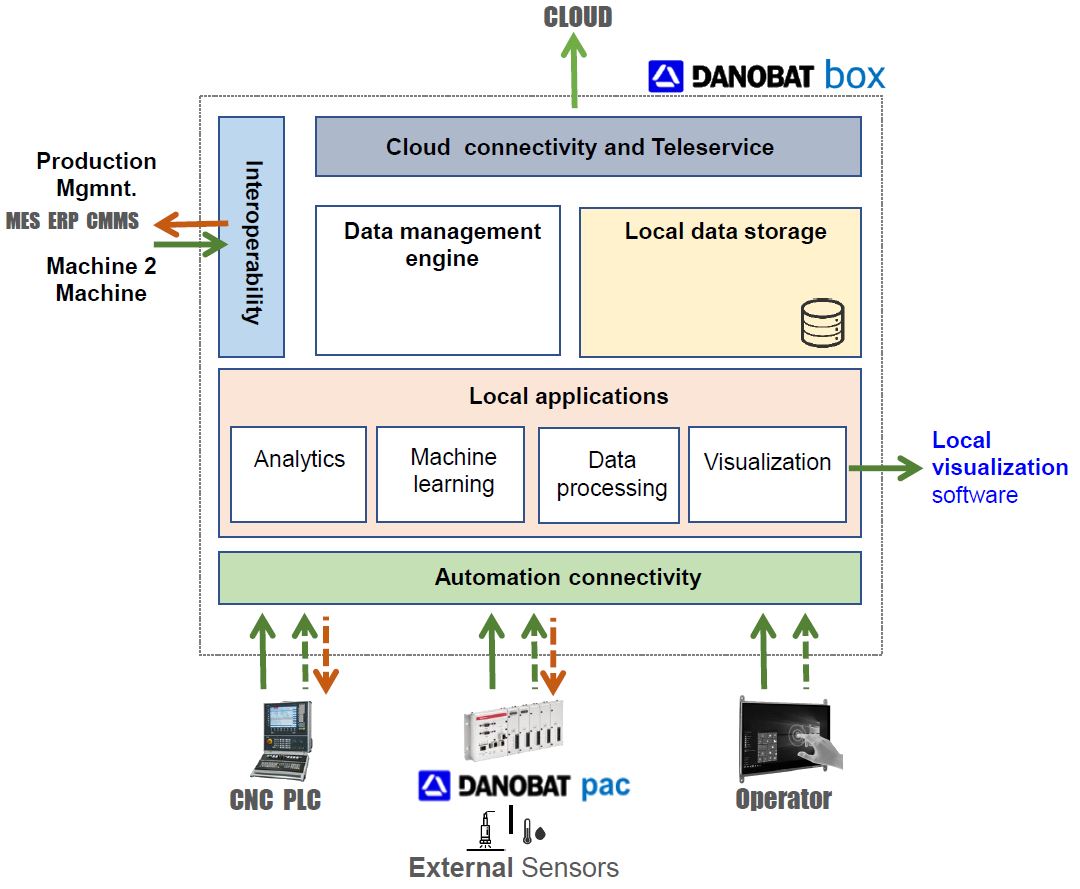

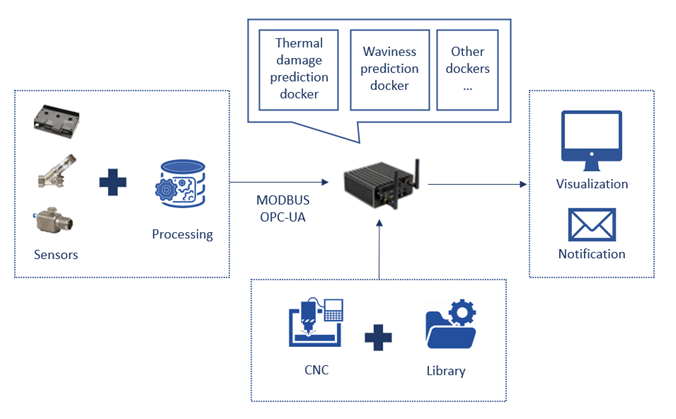

Within the DAT4ZERO Project, the system has been adapted to the specific needs of FERSA bearing manufacturing in the pursuit of defect-free grinding processes, such as ridges or burns. To achieve this, data has been collected from diverse and heterogeneous sources such as external sensors for power, temperature, flow, concentration, or vibrations. Similarly, leveraging sensor fusion capabilities, data has been collected from the numerical controls of the NOVA machines used in the manufacturing line to ensure traceability of process data with preprocessed indicators obtained from the PAC. By using communication protocols such as MODBUS or OPC-UA, data time-stamping has been ensured.

Figure 2: Developments of the digitally-enhanced monitoring system applied to Fersa production line.

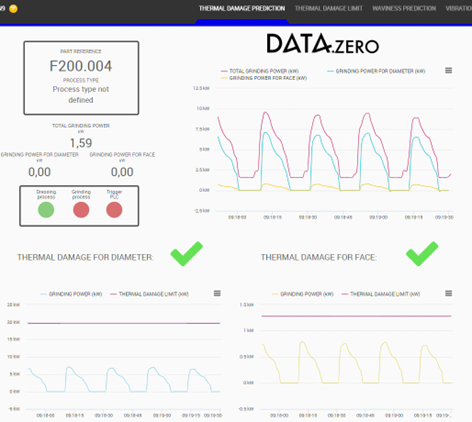

Predictive defect models have been dockerized within the system, and dashboards have been created for visualizing acquired data and results obtained from the models. By utilizing indicators, it is possible to notify the operator when there is a risk of defects appearing, allowing for efficient action to be taken.

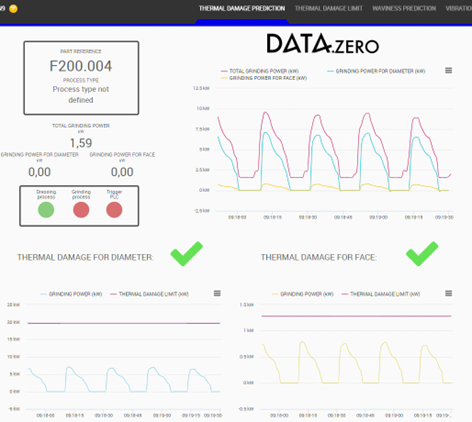

In the case of predicting thermal damage or burning, the tool compares the power consumed by the grinding process with a limit calculated by the model based on theoretical formulation and experimental data. If the consumption exceeds the threshold, there is a risk of thermal damage, and a notification is sent.

Figure 3. Predictive tool for thermal damage in workpiece surfaces.

In the case of predicting waviness defects on the surface of the workpiece, visualization is based on the analysis of indicators obtained from the vibration signals of the accelerometers installed on the machines and the values of the actual speeds governing the grinding process. This allows the system to alert when certain relationships are met, indicating the possibility of specific waviness defects occurring.

Figure 4. Predictive tool for waviness avoidance.