Partners

The partners of DAT4.Zero

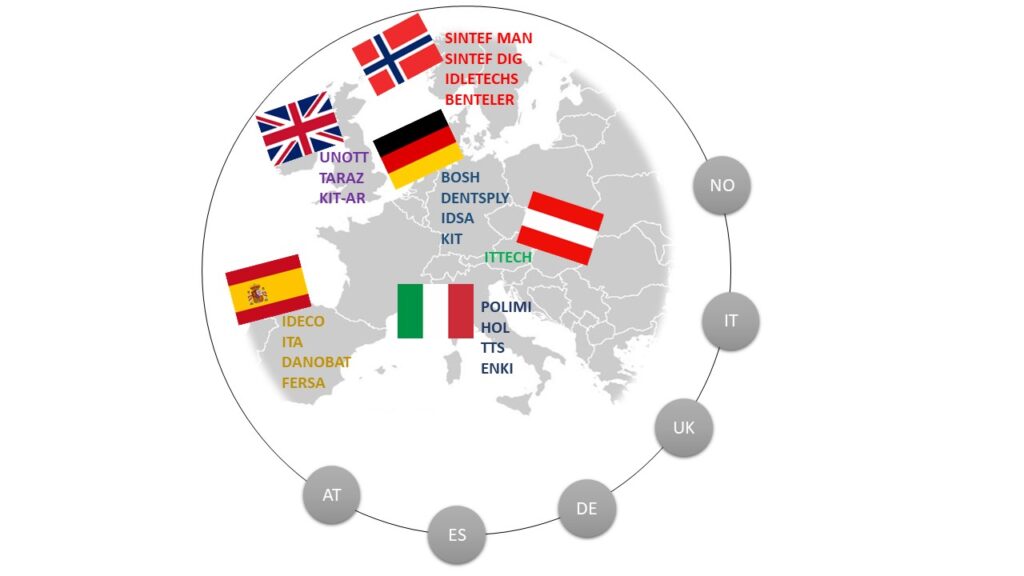

The team for the DAT4.ZERO project consists of 20 highly qualified industrial and research organizations: 3 R&D Companies (SINMAN, SINDIG, IDEKO); 4 Research Institutes (POLIMI, UNOTT, KIT, ITAINNOVA), 6 SMEs (TARAZ, KIT-AR, HOL, TTS, IDLE, TTTECH), 1 Association (IDSA) and 5 Pilots (BENT, DENSTPLY, FERSA, DANOBAT, ENKI and BOSCH). Concerning the geographical distribution, partners, DAT4.ZERO gathers partners from 6 countries: Norway, Italy, UK, Germany, Spain and Austria. A brief overview of each partner is provided below.

Map of partners

Partner contributions

SINTEF Manufacturing AS (SINMAN) is Norway’s leading centre of expertise in manufacturing and has ambition of being a world leading Institute in Manufacturing. The Department of Industrial Ecosystems (IE) is a R&D department within the field of advanced manufacturing, product design and production innovation with expertise within leadership, quality assurance, electronics, automation, innovation, material, design and manufacturing technologies. Our core strength is our collaboration with industry, business and academia to transfer theory into practical and cutting-edge solutions.

SINTEF Manufacturing is coordinating this project and IE, the group of Digital Manufacturing has leading roles in several WP in the project.

SINTEF AS is represented in this consortium by the SINTEF Digital institute. SINTEF Digital employs 400 people and conduct research and innovation in digital technologies and technology-oriented social sciences. Our multidisciplinary knowledge base is used across all industries and help our clients exploit and meet the opportunities created by digitalisation and digital transformation.

SINTEF Digital providing its expertise in developing solutions such as virtual sensors for data reliability and validation. In addition, SINTEF Digital will contribute to the integration activities.

Politecnico di Milano – Department of Mechanical Engineering

Politecnico di Milano is the leading Italian technical university where 40,000 engineers, architects and designers are educated each year.

The Manufacturing and Production System Lab is part of the Mechanical Engineering Department (POLIMI-MECC). Its main research topics concern the area of transformation processes of industrial products ranging from mechanical and technological characteristics of transformed materials to methodologies and tools for designing processes, the planning, management and control of manufacturing and assembly systems.

POLIMI will develop methodologies for modelling and simulation with the aim of rapid line qualification and reconfiguration. Moreover, POLIMI is responsible for the Scientific Coordination of the DAT4ZERO project.

University of Nottingham has excellent research credentials both regionally and globally. UNOTT has long standing critical mass within its research Institutes and Centres specialising in advanced manufacturing, and vast experience working on large scale collaborative EU projects.

The Institute for Advanced Manufacturing (IfAM) at UNOTT has a world-class reputation for research and a current portfolio of greater than £50 million. UNOTT will lead all sensor development activities. They will ensure that the sensors and analysis approaches for the pilot lines are the most appropriate available to the consortium, or wider if necessary. They will also work with the partners on uncertainty analyses for the sensing solutions.

Karlsruhe Institute of Technology

Karlsruhe Institute of Technology (KIT) is a higher education and research organization established on 01/10/2009 as merger of the University of Karlsruhe, one of Germany’s leading research universities, and Forschungszentrum Karlsruhe, one of the largest research centres in the Helmholtz Association.

KIT will be involved in the project with its Institute of Production Science (wbk). wbk focuses on applied research, education, and innovation, particularly in the fields of Surface engineering, process automation, production system planning and production metrology. In the DAT4ZERO project, wbk role is to ensure the data acquisition, data analysis and knowledge extraction for the quality control loop in the Sirona end user case. Additionally, wbk focus lies on data and model reliability (models based on artificial intelligence) for the series production in collaboration with the Bosch use case.

Founded in 1986, IDEKO is an industry driven Spanish Technological Centre (private and independent), specialised in machine tools and advanced manufacturing technologies, with the aim to promote technological innovation of its customers. It is part of DANOBAT Group machine tool builder and Mondragon Corporation.

IDEKO will focus on the activities of exploitation, innovation management and IPR protection. IDEKO will be also responsible for the requirements of the data reliability and repeatability and the evaluation of the KPIs and will be involved mainly in tasks of multi-sensor selection and integration and in data analytics and knowledge extraction.

TARAZ Metrology is a spin-out company from the Manufacturing Metrology Team of the University of Nottingham.

TARAZ will develop and commercialises advanced optical metrology processes, instruments and systems for a range of application sectors. It is responsible for the development of inspection systems for each pilot line.

KIT-AR is a recent spin-off from University College of London, SINTEF and HighSkillz Ltd.

Based on results of the H2020 HUman MANufacturing RIA project. KIT-AR provides a SaaS consisting of an industrial AR solution combining machine learning to provide advanced intelligent model-based stepwise instructions to empower the worker on the manufacturing shop floor. KIT-AR is responsible for the development of the DQM analytics toolkit. In addition, KIT-AR will focus on the human in the loop, engaging the human operator to play a significant role in ZDM.

Instituto Tecnológico de Aragón

Instituto Tecnológico de Aragón (ITAINNOVA) is a non-profit technology centre whose main objective is to promote competitiveness in the industrial sector by means of the development, acquisition, adaptation, transfer, and dissemination of innovative technologies.

ITAINNOVA works on 5 main technologies: Materials Engineering, Robotics & Mechatronics, Power Electronics & EMC, IoT & Blockchain and Big Data & Cognitive Systems. Its main tasks in the project will be the data processing, data analytics, development of data-driven models and real time smart controllers in the FERSA end user case, as well as traceability and trust with Blockchain.

Holonix is a private Italian company, specialised in ICT solutions for the manufacturing domain. The company has extensive experience in collecting, aggregating, analysing data from multiple sources and make them available for the development of a complete digital representation of the working environment, and for the monitoring, control and maintenance of the production assets.

In DAT4.Zero, Holonix will ensure the DQM platform development; Holonix tool, I-Like Machines (ILM), will be used in order to gather data from machines and from end user interactions giving a first semantic meaning. Moreover, ILM will be enriched and improved to give to pilots of DQM platform the possibility to have real time information monitoring each module advance.

TTS Technology Transfer Systems SRL

TTS was founded as a spin-off of the National Research Council of Italy in 1993. TTS expertise lies with the development of a digital factory representation, that can be then linked and continuously updated with data coming from the real factory exploiting the CPS paradigm: this technology is used for setting up new plants, testing PLC logics and as a monitoring system for production plant behaviour. TTS is also member of EFFRA (“European Factories of the Future Research Association”).

Idletechs AS is a software company focused on delivering solutions for process optimization to the industry, based on the combination of physics based- and data driven models (hybrid modelling) with a focus on Explainable AI.

TTTECH Industrial Automation AG

TTTech Indu is based in Vienna, Austria and operates under the umbrella of the TTTech Group, a technology leader in real-time networking and safety controls, with cross-industry experience from more than 20 years of operation.

Its industrial edge computing software delivers modular building blocks for secure data access, real-time control and functional safety, with datacenter-like management and orchestration. Thanks to these innovative products, machine builders can deliver data and offer services to customers from machines installed anywhere in the world.

TTTech Indu, participates in the definition of the requirements and reference architecture for DQM and brings in requirements based on its expertise in the area of communication in the safety-critical networking layers, and in fog and edge computing. Furthermore,

TTTech Indu will assist for data management solutions, to support deep analytics and visualisation at the device, in the factory or in the cloud.

International Data Spaces e. V. (IDSA) is an international association under German law with legal seat in Berlin, German, and its offices in Dortmund, Germany. The International Data Space (IDS) enables a reliable exchange of data with common rules for all companies – based on an open reference model.

Based on its framework, IDSA will support the technical interoperability within the consortium and between any kind of data endpoints involved in the project. Using IDS connectors partners will be able to share any kind of assets in a secure way.

Benteler Automotive Raufoss AS

Benteler Automotive Raufoss (BENT) is part of Benteler group and supplies customers with crash management systems as well as structural and chassis parts. At Raufoss premises there is the complete value chain from processing raw aluminium to finishing final product at one location.

In view of the long value chain and multi-product lines, the pilot case will focus the efforts of this project on the last end of the value chain which constitutes the pace-maker process with defined system boundaries, state of the art machines and possibility for integration of digital technologies for enabling ZDM.

The KPIs that the partner wants to improve are about scrap rate and equipment performances.

SIRONA Dental Systems GmbH is a part of the Dentsply Sirona company group, one of the world largest manufacturer of dental products and technologies for dentists and dental technicians. Dentsply Sirona provides dental professionals and technicians with a comprehensive range of product solutions for dental and oral health.

Dentsply Sirona has long-term experience in the development and manufacturing of gears for dental handpieces, filigree high‐precision products with tolerances of only a few micrometres and whose components are often only a few millimetres in size. Even the smallest deviations in the components’ dimension have an impact on the overall product functionalities.

With the help of multisensory technology and artificial intelligence, developed in the DAT4.Zero platform, the partner goal is to reduce scrap, improve productivity and increase components’ functionality, strengthening competitiveness.

FERSA Bearings is a Spanish multinational company involved in the design, development, manufacture and distribution of high-quality complete bearing solutions.

FERSA base their business plan on the development of high added-value products that involve a continuous effort in R&D and in improvements of their whole manufacturing chain.

With DAT4.Zero FERSA aims at achieving and ensuring optimal bearings manufacturing quality (i.e., reduce scrap and increase production efficiency) in a specific production line, which involves the machining of the inner and outer rings, washing, assembling of rings with rollers and cages, and quality controls.

Founded in 1954, DANOBAT is part of the DANOBATGROUP and one of the global leaders in the design and manufacture of advanced technology and high-performance Grinding Machines, Turning Machines, Sawing & Drilling Machines, Punching Machines, Composite Parts manufacturing automation and Railway Systems automation. Its manufacturing plant in Spain participates to the DAT4.Zero project.

The main role of DANOBAT within DAT4.ZERO project will be the integrator of technologies into the pilot lines, acting as a link between the technology providers and the end-users, focusing on tasks related to multi-sensor/actuator integration and validation, connectivity of machines to the cloud and user-driven data visualization.

ENKI s.r.l. produces one-of-a-kind customized micro-intravascular catheters, high value single-use products that find applications in oncology, angiology, angiography, angioplasty where the demand for customized products and miniaturized products is a significant trend. In the last years, the size of the microtubes composing these devices has been drastically reduced in order to enable applications on smaller arteries, with a tremendous impact on the number of curable diseases, ultimately saving human lives.

The Bosch company is a renowned manufacturer of common rail injectors. The production plant in Homburg represents the tail unit in its international production network for the manufacture of injectors for commercial vehicles. The injector assemblies and their components are developed and tolerated by the project partner. The components are manufactured partly at the project partner’s plant in Homburg, partly at other production sites of the project partner and partly by various suppliers. Furthermore, the assembly and functional testing of the injectors takes place at the Homburg plant.

The partner’s objectives are to reach a complete, digitalized production line, enhance training systems, and avoid error propagation throughout the line.