How we will develop digitally-enhanced solutions to avoid defects in grinding processes

Article

Solving defects in grinding processes

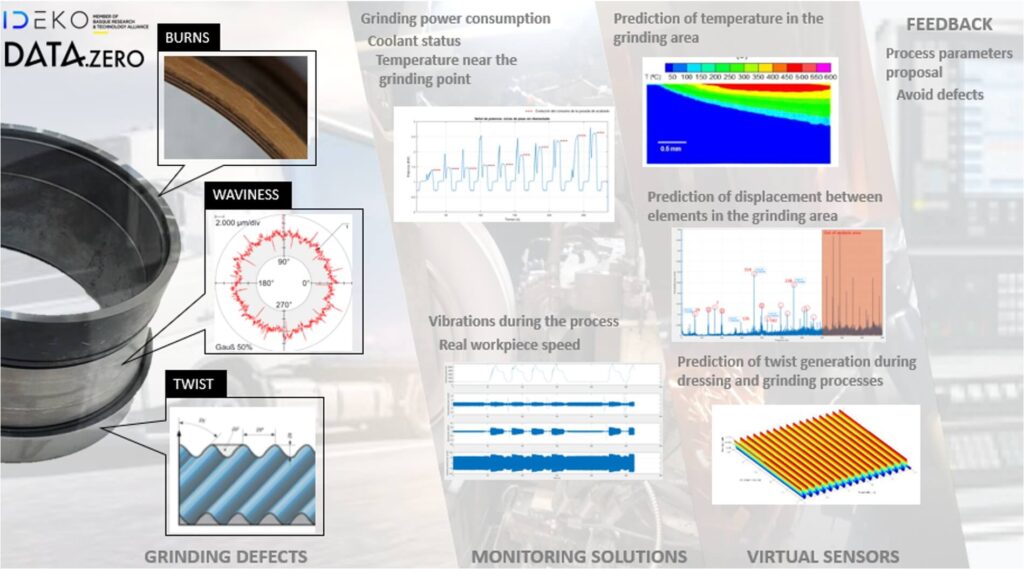

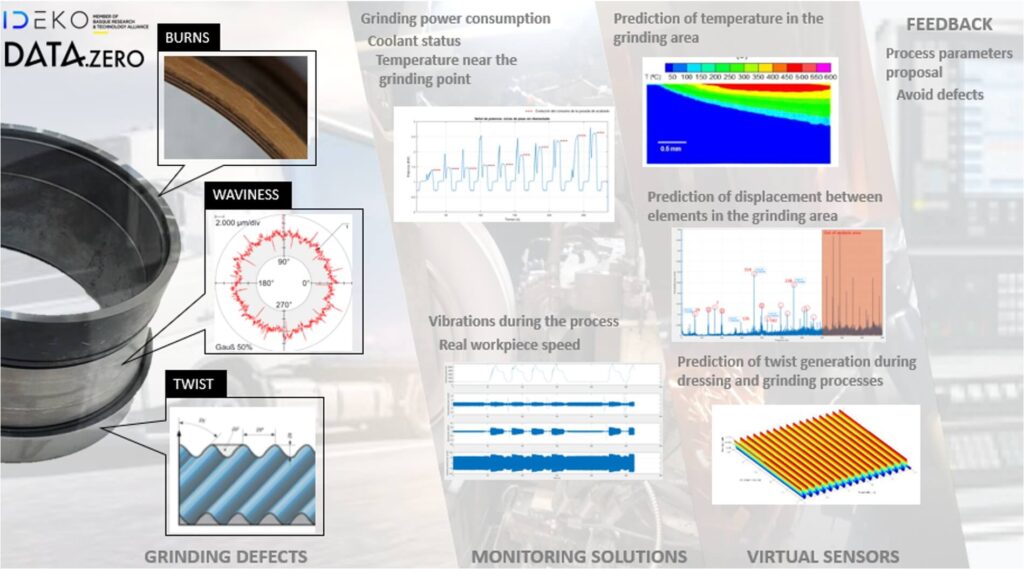

Within Work Package 2 of DAT4.Zero, IDEKO proposes monitoring solutions for the prediction of common defects related to the grinding processes, such as the generation of grinding burns or pattern-like marks on the ground surfaces.

The proposed solutions will be related to:

- The development of virtual sensors to predict the generation of defects during the grinding process based on the data obtained from different sensors,

- The utilization of preprocessing algorithms for extracting the most relevant information and

- The generation of analytical and data driven models for the knowledge extraction.

Once the defects are predicted, feedback will be deployed to assist the operator in the decision of selecting the most suitable process parameters for avoiding the defects.

The next figure shows the relevant specific tasks to be carried out by IDEKO within the DAT4ZERO project:

Figure 1. Relevant tasks by IDEKO within DAT4.ZERO project.

Practical implementation in a production line

These solutions will be implemented in Fersa’s production line of wheel hub bearings for buses and trucks.

The main defects in these parts are related to the appearance of burns in the flange surface, undulations or waviness in the raceways and twist patterns in the sealing surface. All of them affect the correct performance of the bearings regarding the bearing life, generated noise and protection oil leakage respectively.

Currently the measurement of these defects is done post-process which takes too long, however the in-process measurement is a very difficult task due to the harsh environmental conditions because of the coolant influence and the high temperatures in the grinding area.

Therefore, the predictive approach fits perfectly with the aim of preventing the generation of the defects.

About IDEKO

IDEKO, as a technological center in advanced manufacturing, is specialized in the development of technologies and solutions for zero defect manufacturing. IDEKO is a partner in the DAT4.Zero project.

About FERSA

FERSA Bearings is a Spanish multinational company involved in the design, development, manufacture and distribution of high-quality complete bearing solutions. FERSA is partner in the DAT4.Zero project, and it represents one of the five industrial pilots.